Motion controllers

Motion control is an important aspect of robotics which helps us determine the velocity and position of a robot (or any mechanical device).

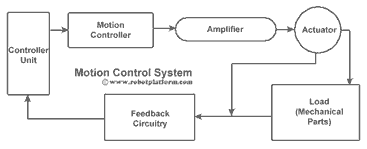

In the below diagram, a complete motion control system is portrayed. However it is not obligatory to include all of these devices in a motion control system.

- A controller (generally a microcontroller) sends signals to motion controller.

- Based on the input signals, a motion controller sends commands to an amplifier for position and velocity control

- An amplifier takes commands from a motion controller and generates current required to drive the actuator

- When electrical energy is supplied, the actuator converts it into mechanical energy creating torque

- Mechanical parts attached to an actuator creates a motion (generally linear or rotary) from the torque generated

- A feedback circuitry provides feedback (like position, velocity, force, etc.) to the controller unit completing the loop.

The most important aspect of motion control is Motor control since most of our mobile robots use motors.

Motor Controllers

Motor control would mean controlling the speed, torque, start-stop, direction (forward or reverse), etc. which can be automatic, remotely controlled or manually operated. Control signals can be either analog or digital.

Starting & Stopping a Motor

In small and low voltage motors, "starting" and "stopping" is simply connecting motor leads to a power source, through a switch, or a simple circuitry. However large motors require a contactor or a circuit breaker to operate. For building most small and mid-sized robots, we can stay within the limits of switches or a control circuitry.

Operation control

Motor’s Operational control can be divided into two categories

- Speed control

- Feedback control

Speed control: The purpose of a speed control is to receive commands from controller and drive the motor in that demanding speed. Controllers can only send signals to operate at a specified speed and may not measure or guarantee that the motor is running at a particular speed.

Feedback control: This confirms if the motor is running at a particular speed and/or driven to a desired position.

There are many types of DC motors and so are the different types of controllers. In the next section we will explore the different speed control techniques and in later section we will study different feedback mechanisms used.

Do you have anything to say?

Visit the Forum to discuss, learn and share anything related to robotics and electronics !!