Types of Robot Actuators

As discussed in the previous section, an actuator is an electromechanical device which converts energy into mechanical work. There are several types of actuators used in robots. In this section, we will classify the various actuators available, based on the type of energy source used.

Pneumatic actuator

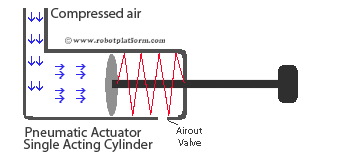

These actuators use the principle of Pneumatics (where pressurized air/gas) to create motion (or perform work). Pneumatic actuators can be used to produce both rotational motion and linear motion.

The basic design includes a Cylinder, a Piston and few supporting components like valves, springs, stoppers etc.,Compressed Air or pressurized gas is filled into the cylinder and the compressed air tries to expand to reach atmospheric pressure. This expansion is forced towards a piston or any other mechanical device which makes an attached object move. Depending on the design, it can either create rotational motion or linear motion. Most air compressors and air pumps use this principle due to its simplistic design. Image shows single acting cylinder where a spring pushes the piston back to its base position. In a double acting cylinder, another valve on other end of the cylinder pushes the piston back to base position.

The basic design includes a Cylinder, a Piston and few supporting components like valves, springs, stoppers etc.,Compressed Air or pressurized gas is filled into the cylinder and the compressed air tries to expand to reach atmospheric pressure. This expansion is forced towards a piston or any other mechanical device which makes an attached object move. Depending on the design, it can either create rotational motion or linear motion. Most air compressors and air pumps use this principle due to its simplistic design. Image shows single acting cylinder where a spring pushes the piston back to its base position. In a double acting cylinder, another valve on other end of the cylinder pushes the piston back to base position.

Pneumatic actuators are mainly used for systems which require quick and accurate response. These actuators are clean, make less noise and relatively compact in their design.

Air Muscles: To replicate muscles in robots, Air muscles (also known as pneumatic air muscles - PAM) are used. PAM’s generally consist of a rubber bladder covered by a braided fiber mesh. When pressurized gas/air is inflated, it expands radically and when deflated, it contracts. Air muscles are inexpensive, light weight, exhibit a phenomenal strength to weight ratio, easier to build, flexible compared to other electric and hydraulic actuators, durable, safe, and also easy to use under water.

Hydraulic actuator

According to Blaise Pascal, when there is an increase in pressure at any point in a confined incompressible fluid, then there is an equal increase at every point in the container. Hydraulic actuators are designed based on this principle (Pascal’s law).

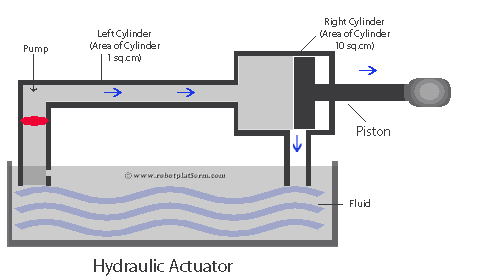

To understand how hydraulic actuators work, let us take an example of two cylinders, connected together, as shown in the image. Suppose one cylinder has a cross-section area of 1 square centimeter and the second one has a cross-section area of 10 square centimeters. If the cylinders are filled with incompressible fluid and 1 unit of pressure is applied to the left cylinder pushing the pump (actually liquid) by 10 centimeter, then the resulting force acts on the right cylinder pushing the piston by 1 centimeter, but with a force of 10 units. This means applying 1 unit of force produces 10 units of force on the other side.

Hydraulic actuators are majorly used for systems which require very large force, but not very restrictive on positioning and accuracy.

Hydraulic Cylinder: Generally referred as linear hydraulic motor is used when a robot requires linear force. These actuators are powered by hydraulic fluids. When hydraulic pressure acts on it, a piston connected to a piston rod within the cylinder moves back and forth creating linear motion. Hydraulic cylinders can also convert hydraulic pressure into rotation creating a rotary actuator, based on the mechanical design.

Piezoelectric Actuators

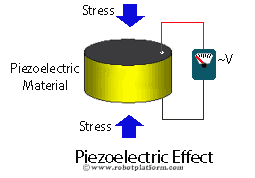

These actuators use piezoelectric effect to create motion. For those who are not aware of piezoelectric (piezo means press, or apply pressure) effect, it is a charge that accumulates in certain ceramic materials and crystals (like quartz, tourmaline etc.) when a mechanical stress is applied. This is known as piezoelectric effect where deformation of the material creates a voltage difference.

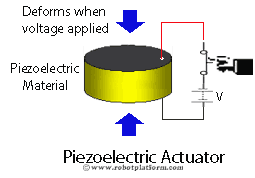

When an electricity flows through a piezoelectric material, it creates a physical deformation which is proportional to the applied electric field, known as indirect piezoelectric effect. This precise deformation can be used to position objects with extreme accuracy, almost at µm accuracy.

Piezoelectric actuators are used in Loudspeakers, Piezoelectric Motors, acceleration sensors, vibration sensors etc., and can be used to create either rotational or linear motion. The strokes of these actuators can also be amplified if required, because direct strokes from these peizoelectric actuators are generally less than 100 µm.

Ultrasonic Piezoelectric Actuators

Similar to Piezoelectric actuators as discussed earlier, Ultrasonic Piezoelectric actuators work on the principle of piezoelectric effect. A travelling wave excites a stator surface (material exhibiting piezoelectric effect) which behaves like an elastic ring and produces elliptical motion at the interface of the rotor, which propels the rotor and the drive shaft connected to it.

Ultrasonic Piezoelectric actuator can induce either rotational motion or linear motion. These actuators provide extremely precise movement with good torque to size ratio, and used in most camera autofocus lenses and watch motors.

In the next section we will discuss about Shape Memory Alloy, Combustion Engine and Electric Actuators.

Do you have anything to say?

Visit the Forum to discuss, learn and share anything related to robotics and electronics !!